-

SnuubingAbstract:

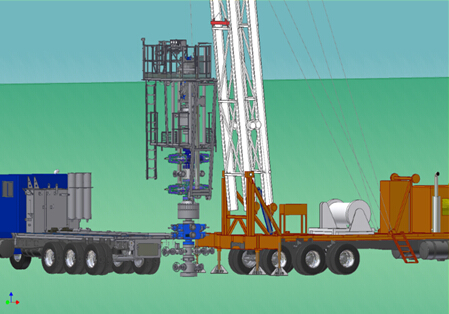

The Snubbing Operation is one of the most adaptable techniques available in the upstream oil & gas industry.

Details

History of Snubbing

Snubbing is the control of a tubing string while running it in or out of a well bore under pressure. This is accomplished by holding the tubing with inverted slips. One set of slips, stationary, holds the tubing while the other set traveling is used to force the tubing in or to hoist the tubing in a controlled manner; using cables and sheaves to allow the drawworks to control tubing movement. This idea was conceived and developed by Herbert C. Otis in 1929. In 1960 Cicero C. Brown invented the hydraulic jack giving the snubbing operator complete control over the insertion and removal of tubing thus eliminating the need for liaison between the service/drilling rig operator and the snubbing operator. This method enabled the snubbing operation to be used as a self-contained modular unit.

The development of the hydraulic snubbing unit has expanded the horizons of the process tremendously; previously snubbing was considered “disaster services”, as it was used as a last resort to get someone out of a terminal problem. The “disaster services” element is still evident but since the speed and efficiency of the hydraulic snubbing unit has been proven, it has been increasingly used as a production tool. The portability of the modular self-contained snubbing unit has also made it a viable workover/completion unit, in areas that previously would have been the domain of the service rig. This is due primarily to economics. It is possible to develop a tremendous lifting power where a conventional workover unit would require structural changes and/or expensive transportation modifications.

Hydraulic units have proven particularly effective in offshore applications where production facilities may have to be moved or platforms radically modified to accommodate the size and weight of a conventional drawworks unit. With a snubbing unit all force and weight is transferred to the well casing making it unnecessary to modify facilities. These units have also effectively been used in the desert, jungle, and congested urban areas where the logistics of moving a large workover unit are considered unsurmountable and not economical.

The hydraulic snubbing unit was a vast improvement over the cable and sheave arrangement, but the self-contained aspect was not, in all cases, as advantage as there is a high availability of service units. Self-contained units were expensive when service work was not limited to snubbing as round-tripping with a derrick is much faster. They are still used for completions and pulling tubing that is to be laid down and replaced by another string. They are also used for through-tubing 1”, 1.5” work milling sulfates, hydrates and fishing wireline tools, etc.

OPERATIONS

Operationally, snubbing has not changed significantly since 1929. Some of the things done with snubbing units have changed, in that we have learned that with “planning and preparation” almost anything can be done. The melding of wireline service and snubbing has made it possible to safely run and pull complex completions and fishing strings, here-to-fore unheard of, with complete safety. This has been achieved by “hanging off” tubing by use of slip rams and/or pipe rams in the snub position, adapting to wireline and lubricating long bottom hole assemblies out of or into the wellbore rather than using the more traditional method of rigging up the snubbing unit on flanged riser spools to accommodate the length of completion tools. This allows, particularly, the running of long sand screen assemblies, slotted liners, perforated pups, etc., quickly and efficiently. Being able to “lubricate” out allow the safe recovery of expended tubing conveyed perforating assemblies, long completions and fishing tools while still being able to run tubing conventionally with the pulling unit, without “crowning out” because riser spools have taken available space.

Common Applications for Snubbing

1. Jointed pipe operations

2. Asphaltene, paraffin, and scale removal

3. Completions, single and dual string

4. High pressure workovers

5. Deploying and retrieving packers, bridge plugs and other down-hole equipment

6. Hydrate washing

7. Installing sand screens

8. Deploying and retrieving acidizing tools

9. Fishing lost tools

10. Milling operations

11. Under-balanced drilling

12. Blow-out control and re-entry work

13. Deploying and retrieving tubing conveyed perforating guns

14. Jointed pipe operations under pressure when a coil tubing unit is beyond it’s design parameters

The Advantages of Snubbing

1、Eliminates the need for kill fluids

2、Reduces formation damage

3、Saves time and money

4、Environment friendly