-

Xushen 1-1 VerticalAbstract:

In 2008, Top Well was contracted to pull a tubing string that had obstructions in the bottom of the string from previous operations. The previous efforts had attempted to plug the tubing in order to remove it from the well under pressure

Details

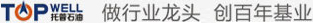

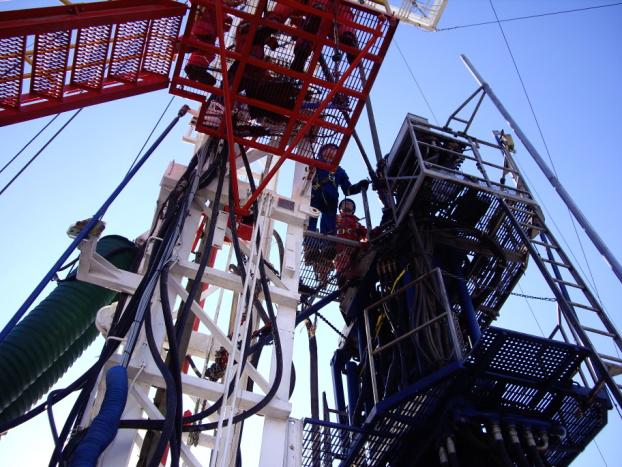

Top Wells XJ 550 Workover Rig and S-9 Snubbing Unit

Synopsis: Obstructed / Leaking Tubing Change out with New Chrome Pipe

Well Data:

- Tubing: 89mm (3.5”) EUE and 73mm (2.875”) Fox Cr13

- Casing: 177mm (7”)

- Max Pressure: 19 Mpa (2750 Psi)

- Well Depth: 3400 Meters (11150’)

In 2008, Top Well was contracted to pull a tubing string that had obstructions in the bottom of the string from previous operations. The previous efforts had attempted to plug the tubing in order to remove it from the well under pressure, but after setting several bridge plugs it was determined that the tubing integrity was suspect as it was not possible to de-pressurize the tubing after setting plugs repeatedly.

Top Well utilized both our SJ 550 workover rig and our S-9 Rig Assist snubbing unit to complete this well.

The customer wished to remove the existing string and replace it with a smaller inner diameter string in order to provide more flow velocity. The existing 89 mm (3.5”) EUE string was in poor condition and efforts to bleed it off after plug setting were unsuccessful. Top Well designed a “balanced kill” plan to control the tubing pressure during the trip out.

Two more bridge plugs were set in the tubing above the bridge plugs set two years before, and the tubing was filled with produced water. The tubing head was removed and the primary BOPs and snubbing unit rigged in. The stack configuration was as follows:

- 10M {70 MPA} Flow Cross c/w 10M {70MPA} double Gate Valves both sides

-

10 M{70 MPA} double gate BOP

- Bottom Cavity dressed with Blind rams

- Top Cavity dressed with Blind rams

- 10 M {70 MPA} single gate BOP dressed with 89mm (3.5”) safety fronts

- 10 M {70 MPA} single gate BOP dressed with 89mm (3.5”) safety fronts

- 10 M {70MPA} x 5M {35MPA} crossover

- 5M {35MPA} rig assist snubbing unit dressed for 89mm (3.5”)

The casing pressure was aligned to a choke manifold and then vented to a flare pit. Pressures were carefully managed throughout the trip out to prevent flow from the tubing string.

Once the top bridge plug was reached, there was 100 meters of tubing remaining in the hole with questionable integrity. Pumping equipment was aligned to the casing side and the produced water was introduced to the casing at a rate sufficient to control the pressures of the casing.

Hot Tapping the BHA Damaged Bridge Plug Set Two Years before Job

Because there was potential for bottomhole pressure to be trapped between the bridge plugs, Top Wells hot tap equipment was utilized to tap and bleed off the pressure trapped between each of the bridge plugs set in the bottom section of the string. (Five in total) The remaining tubing was stripped above the blind rams and the well was secured. The well was immediately flowed back to recover the total amount of fluid pumped into the casing during the previous operation. The well sustained no damage during the procedure.

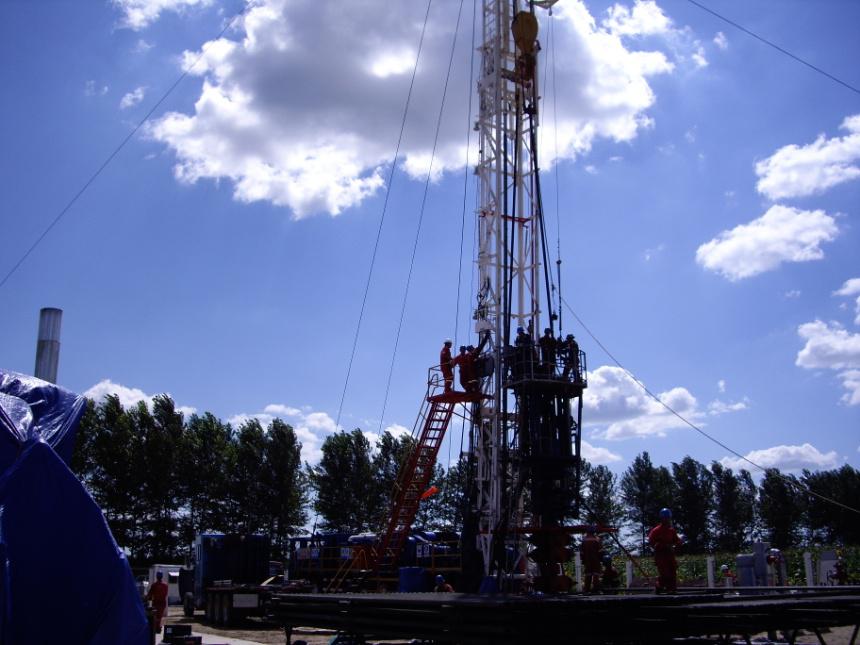

All the handling equipment was changed over to run 73mm (2.875”) chrome tubing. The slips of the unit were dressed with special non-marking dies, and the power tongs dressed with chrome running dies and hooked up to a computer to ensure proper torque on each connection.

All pipe rams were changed over to 73mm (2.875”)

A new string of 73mm (2.875”) Fox premium chrome tubing was snubbed into the well using Top Wells chrome handling equipment, and landed at 3200 Meters. Tubing pressures were controlled with a Top Well “Knock Out” plug. There was an Otis “XN” profile placed one joint off bottom to facilitate future pressure operations. The tubing was successfully landed and all equipment rigged out. The well head top section was installed, and the tubing equalized. The annulus was aligned through the choke manifold to the flare pit. The annulus was flowed to lower the pressure on the backside approximately 4 Mpa below tubing pressure. At this point the knock out plug expended and fell to the cellar of the well. The well was shut in and turned over to production.