-

Xushen 1-Ping-1 HorizontalAbstract:

TOP WELL has performed snubbing services successfully throughout China including many main domestic oil and gas fields

Details

Synopsis: Multiple Stage Surge Fracturing Treatments

Well Data:

- Tubing: 73 MM (2.875”) EUE P110

- Casing: 177mm (7”)

- Max Pressure: 40 Mpa (5800 Psi)

- Well depth: 3400 Meters (11,150’)

In 2008, TOP-WELL coordinated with HALLIBURTON to conduct SURGIFRAC operations successfully in the Daqing oilfield XuShen1-P1 well. Our team designed the operational programme according to the features of a horizontal well. The Surgifrac job achieved multi-perforation and fracture processes during one trip in the hole. The technology avoids damaging the formation from kill/frac fluids effectively and decreases the operational scale and material consumption.

Our customer wished to perform multiple fracturing treatments on a long horizontal section of this well. The need to move the tubing after each treatment in approximately 100 meter lengths without killing the well necessitated the use of one of our snubbing units. Because the well had a conventional workover rig installed on to leading up to the fracturing treatment it was identified that a rig assist unit would be best suited for the job. Top Well and Halliburton collaborated with the customer during the planning stages of the work, careful consideration was undertaken to ensure a smooth outcome for the job.

The well was dead prior to the fracturing treatments, so the workover rig was utilized to run the following fracturing string to the depth for the first treatment stage. The tubing hanger was landed and the 105 Mpa (15K) tubing head installed. The following tools were run into the hole:

From the bottom up:

- Halliburton Surge Frac Tools

- 2.875” {73mm} 10’ {3. 04 m} P110 Pup Joint

- Otis “X” nipple c/w 2.31 profile

- 2.875” {73mm} 10’ {3. 04 m} P110 Pup Joint

- Otis “X” nipple c/w 2.31 profile

- One Joint 2.875” {73mm} P110

- 2.875” {73mm} 2’ {.60 m} P110 Pup Joint

- 10912’ {3326 m} P110 2.875” {73mm} tubing

- Otis “X” nipple c/w 2.31 profile

- One Joint 2.875” {73mm} P110

- Otis “X” nipple c/w 2.31 profile

- One Joint 2.875” {73mm} P110

- 2.875” {73mm} 2’ {.60 m} P110 Pup Joint

- 3576’ {1090 M} P110 2.875” {73mm} tubing

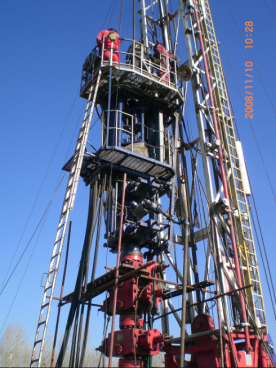

Making Up BHA Xushen 1-Ping-1 prior to first fracturing treatment

The fracturing equipment was rigged in and the treatment was successfully completed. The well was flowed back and the pressure continued to rise until the well was shut in with a pressure of 10 Mpa at surface. Wire line services were rigged in to place tubing plugs in the vertical section of the well in the two “X” nipples. Tubing pressures were bled off, and the fracturing head rigged down.

Setting Wireline Plugs

Top Well rigged in the surface control equipment as follows to allow the tubing string to be raised for the next fracturing treatment.

FROM THE BOTTOM UP:

- 15 M{105 MPA} x 10M {70 MPA} crossover

- 10M {70 MPA} Flow Cross c/w 10M {70MPA} double Gate Valves both sides

-

10 M{70 MPA} double gate BOP

- Bottom Cavity dressed with blind rams

- Top Cavity dressed with Shear rams

- 10 M {70 MPA} single gate BOP dressed with 2.875” {73mm} safety fronts

- 10 M {70 MPA} single gate BOP dressed with 2.875” {73mm} safety fronts

- 10 M {70MPA} x 5M {35MPA} crossover

- 5M {35MPA} rig assist snubbing unit

Primary Bop Stack Snubbing Unit Rigged In

The entire BOP stack was pressure tested to 70 Mpa (10K) and snubbing unit was pressure tested to 35 Mpa (5K). The tubing hanger was stripped out of the hole using the snubbing unit BOPs and jacking system. Approximately 100 meters of tubing were pulled out of the hole and the tubing hanger was re-installed. The snubbing unit and BOPs were removed and the fracturing head re-installed in preparation for the next fracturing treatment. Wireline was rigged in and the tubing plugs were removed prior to the next fracturing treatment. This process was repeated for each fracturing treatment.

Upon completion of the fracturing, the fracturing string was pulled out of the hole and the completion string installed.

This well represented the first use of Rig Assist utilization during the “Surgifrac” process in China.